----------

|

Curio's - AKG's 2072 Z 0005 capsule |

|

|

A quick look at the history |

|

|

As far as I can tell, the first "Teflon" CK12 style capsule was designed and manufactured, to offer a modern "Smoother / Transparent" sound, to that of it's "Brass" predecessor. Plus, due to manufacturing technique's, production costs would be far cheaper. |

|

|

This was to be designated the 2072 Z 0001. |

|

|

First used during production of the AKG C414EB series microphones (Including the C414E1 "Remote" versions). Early examples of these microphones being fitted with the remaining stock of the "Brass" CK12 capsules and later models being fitted with the newly introduced "Teflon" CK12 style capsule. |

|

|

The 2072 Z 0001 was soon superceded by the 2072 Z 0003, 2072 Z 0004 and finally, during the early 1980's, the 2072 Z 0005. The later being still in production today (circa 2009). There has never been a 2072 Z 0002 type capsule. |

|

|

"Teflon" 2072 Z 0005 type capsule |

|

|

Please Note - For the sake of convenience and unless stated otherwise, then all further reference to the 2072 Z 0005 capsule (on this page), is to imply the complete range i.e. from the 2072 Z 0001 through to the current (circa 2009) 2072 Z 0005 capsules. |

|

|

Throughout production of the 2072 Z 0005 capsules, many variations and changes in the manufacture of component parts have taken place. |

|

|

1 - Backplate, "Electrode" - Different material and manufacturing technique's used i.e. etched and machine turned. |

|

|

2 - Backplate, "Electrode" wiring - Originally wired to a common "Slide-on" contact, later terminated on Brass pins. |

|

|

3 - Contact "Carrier" - Different colours of material used. |

|

|

4 - Capsule "Frame" - Different colours of Teflon used e.g. a small amount of capsules being manufactured using "Black" Teflon. |

|

However, the sound qualities stayed constant throughout the series, making the above capsules totally interchangeable. |

|

|

The 2072 Z 0005 capsule, is found to be no match for the original "Brass" CK12. Many engineers and musicians finding the acoustic properties, of these "Teflon" capsules, far less musical and useable, than that of the "Brass" CK12. |

|

|

Production of the "Brass" CK12 finally ceased and the "Teflon" 2072 Z 0005 was here to stay. Being used in all of the C414 series microphones, through to the C414B-TL. Also being used in the AKG "The Tube" and the CK4. The later from AKG's CMS range of the 1970's. |

|

|

The C414B-TLII and the C12VR used a different version of the "Teflon" CK12 capsule i.e. type 2072 Z 0009. That is yet another story ..... |

|

| Why could the "Brass" and 2072 Z 0005 capsules sound that different ? | |

|

As already mentioned, on the "AKG "Brass" CK12 capsule" page, ..... "The "Brass" CK12 capsule is probably the most complex of any microphone capsule ever manufactured". |

|

|

1 - The above must surly be one reason why the 2072 Z 0005 is quite different in tonal character. |

|

|

2 - The diaphragm and support ring, 2072 Z 0005, is merely a tight "Snap-fit" into the capsule frame. |

|

|

So, let us take a closer look at the design and assembly of the 2072 Z 0005, then maybe we can appriciate why it sounds different to the original "Brass" CK12. |

|

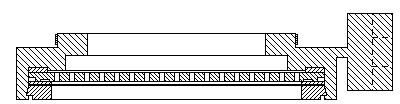

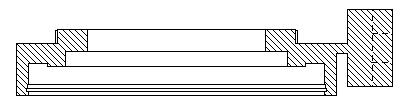

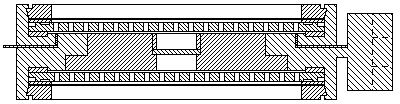

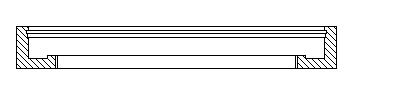

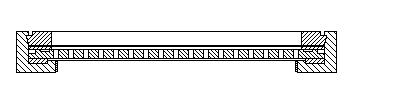

| Sectional views of 2072 Z 0005 capsule | |

| Note - For reasons of clarity, hidden detail and wiring, are not shown. Neither are the drawings shown in true exploded view form, but rather as a group of exploded views | |

|

Let us start by looking at "The Parts", that are utilized in the capsule assembly. |

|

|

Diaphragm Mounting Ring and Diaphragm. Note the tapered edge to enable the "Snap-fit" into the frame. |

|

|

Diaphragm to Backplate, Insulated "Distance Ring" |

|

|

Backplate, "Electrode" |

|

|

Foam Ring |

|

|

Removable half of "Teflon" Capsule Frame. With a "Recess" that allows the diaphragm assembly to be a "Snap-fit" into the frame |

|

|

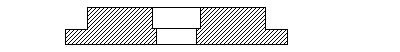

When the above parts are fitted together, we have the removable half of the capsule assembly. Note that the foam ring, between the backplate and frame, is now compressed. Thus all the parts are "Sandwiched" together. |

|

|

Capsule Fame Insulation/Spacing Ring |

|

|

When the parts below are fitted together, we have the Fixed/Mounting half of the capsule assembly. Note that the foam ring, between the backplate and frame, is now compressed. Thus all the parts are "Sandwiched" together. |

|

|

Fixed/Mounting half of "Teflon" Capsule Frame. With a "Recess" that allows the diaphragm assembly to be a "Snap- fit" into the frame |

|

|

Foam Ring |

|

|

Backplate, "Electrode" |

|

|

Diaphragm to Backplate, Insulated "Distance Ring" |

|

|

Diaphragm Mounting Ring and Diaphragm. Note the tapered edge to enable the "Snap-fit" into the frame. |

|

|

For reasons of clarity, the above drawings did not show one of the most important item that helps to control the "Acoustic" properties of the capsule. That being the Teflon contact carrier and stainless steel mesh, known as the "Carrier/Damping" assembly. This is used to help control/correct the frequency response and polar pattern of the capsule. |

|

|

The "Carrier/Damping" assembly consists of 3 parts/components. |

|

|

1 - The acoustic mesh "Locating/Retaining Sleeve" Made from Teflon, and glued into place during construction |

|

|

2 - The "Acoustic Friction Element" Very fine stainless steel mesh, approx' 0.015mm thick and having approx' 8 holes/mm |

|

|

3 - Contact "Carrier" Made from Teflon and used to carry the electrical pick-up contacts for the backplate electrodes and home to the "Acoustic Friction Element" |

|

|

Finished "Carrier/Damping" assembly. The assembly lives in the heart of the capsule, between the rear of the backplate electrodes. |

|

|

Now we have all of the components required to build the 2072 Z 0005 capsule. The removable and fixed halves of the capsule are assembled, together with the associated frame "Spacing Ring" and the "Carrier/Damping" assembly, thus forming the finished unit. |

|

|

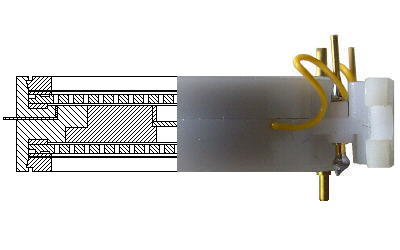

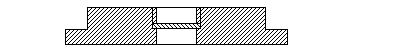

Fully assembled 2072 Z 0005 capsule |

|

|

Cutaway/Sectional view of the 2072 Z 0005capsule |

|

| Let us now dismantle the 2072 Z 0005 capsule, and see what we find ! | |

|

Initially we have the complete capsule assembly, removed from the associated microphone. |

|

|

The capsule consists of two halves. For the sake of convenience, let us call them the "Removable" and "Fixed" halves. The fixed half having the mounting bracket, which unlike the "Brass" CK12, cannot be removed as a separate item. During manufacture, the two halves are screwed together and held in place by a Locktite type of adhesive. |

|

|

So let us start by separating the two halves of the capsule. Now we have the "Removable" and "Fixed" halves. |

|

|

Unlike the "Brass" CK12, where each diaphragm and mounting ring is held in place by 12 screws per diaphragm, the 2072 Z 0005 diaphragms and mounting rings are simply "Popped out" of the "Teflon" frame. The edge of the diaphragm mounting ring is tapered to allow this "Snap-fit" into the "Teflon" capsule frame. |

|

|

Electrical contact with the diaphragm being made via a small screw-in brass contact post. This accepts a slide-on connector or alternatively the screw-in post can be removed, enabling a suitable "Solder tag" to be fitted, before the post is refitted. |

|

|

Very thin insulated "Distance Rings" are used to determine the exact distance, air gap, between the rear surface of the diaphragm and front of the backplate. The distance ring rests on the machined reference, around the outer edge of the backplate. |

|

|

As with the original "Brass" CK12, these "Distance Rings" effecting the sensitivity of the capsule e.g. thinner the ring, the greater the sensitivity. The rings also having an influence on the frequency response and polar pattern of the final assembled capsule. |

|

|

The backplates now come into view. These are held in place simply by compression, due to the "Snap-fit" of the diaphragm and a rear mounted foam ring. Forming a sandwich of the parts. Therefore, at this stage of dismantling the capsule, the backplates will now just fall out of the frame ! |

|

|

Looking at the "Guillotined" marks around the perimeter of the backplates, they would appear to be "Pressed out", rather than machined to the required finish. |

|

|

The backplates would appear to be similar in design and appearance to that of the main backplates of the "Brass" CK12 design e.g. the position and number of holes. However, there is additional engineering, in the form of a recess and machined "Reference" surface, towards the outer edge of the backplate. |

|

|

Both the front and rear backplates sharing a common "Insulated" Teflon contact carrier, known as the "Carrier/Damping" assembly. The gold plated brass contacts are somewhat wider than those used in the 2072 Z 0009 capsule. The contact carrier lives in the very center of the capsule assembly and carries two spring contacts, one on either side of the carrier, thus making electrical contact with the rear of the associated backplate when the capsule is assembled. Each one of these contacts being wired out of the "Fixed" half of the "Teflon" frame, to it's respective brass terminal, allowing for connection to the microphone wiring. The "Removable" half of the frame, just being a carrier for the diaphragm and associated parts. |

|

|

In the center of the Teflon contact carrier, there is a hole of approximately 3.9mm diameter right the way through the mounting. Within this hole is the "Acoustic Friction Element", a piece of very fine stainless steel mesh, which helps to control/correct the frequency response and polar pattern of the capsule. Located and retained in place, by a small Teflon sleeve glued into the carrier. The stainless steel mesh is approx' 0.015 mm thick and the weave of the mesh is approx' 8 holes/mm. A fine/cleaver piece of manufacturing indeed. |

|