----------

|

Curio's- AKG's 2072 Z 0009 capsule |

|

|

A quick look at the history |

|

|

Note - The 2072 Z 0009 capsule should not be confused with the earlier 2072 Z 0005 capsule, together with it's other "Teflon" CK12 style predecessors, as used in many of the older C414 series microphones. For further information, AKG's 2072 Z 0005 capsule. |

|

|

The 2072 Z 0009 capsule was first used in the AKG C414B-TLII (circa 1993) and the AKG C12VR (circa 1994). The later being a revamped version of "The Tube". |

|

|

In the words of AKG, re excerpts taken from their C414B-TLII brochure, "AKG is re-creating the CK12 capsule ....." and from their C12VR brochure, "The capsule was recreated from the original 1950's design, using the latest manufacturing techniques" |

|

|

As most of us are only to well aware, the previous "Teflon" CK12 style capsules, type 2072 Z 0005 and predecessors, never really came anywhere close to the sound of the original "Brass" CK12 capsule. So the introduction of the 2072 Z 0009 was most welcome. |

|

|

"Teflon" 2072 Z 0009 type capsule |

|

|

Looking at the 2072 Z 0009, the most obvious "Cosmetic" difference to the 2072 Z 0005, is that of a small "Indent" of the outer face of the diaphragm mounting rings. This "Indent" being diagonally opposite the electrical terminating pin. The other differences are mostly hidden from view i.e. within the capsule assembly. |

|

| What helps to make the 2072 Z 0009 capsule sound that much closer to the original "Brass" CK12 than the 2072 Z 0005 ? | |

|

1 - The 2072 Z 0009 uses a more complex, internal, acoustic resistive path to that of the 2072 Z 0005, being similar to that of the "Brass" CK12 capsule design. This helping to control/correct the frequency response and polar pattern of the capsule. |

|

|

2 - The diaphragm's used in the 2072 Z 0009, are of a different type to that used in the 2072 Z 0005 capsule. |

|

|

As far as can be determined from physical dimensions, then every other component/part that is used in the construction of the 2072 Z 0009 capsule, is the same as that used in the 2072 Z 0005 capsule. Having said that, then I look forward to be corrected on that fact ..... |

|

|

In the drawings below, these specific items are shown in BLUE. |

|

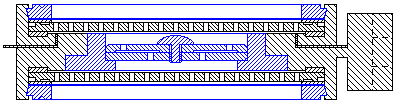

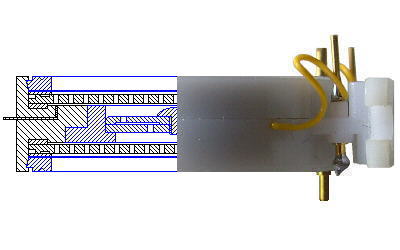

| Sectional views of 2072 Z 0009 capsule | |

| Note - For reasons of clarity, hidden detail and wiring, are not shown. Neither are the drawings shown in true exploded view form, but rather as a group of exploded views | |

|

Let us start by looking at "The Parts", that are utilized in the capsule assembly. |

|

|

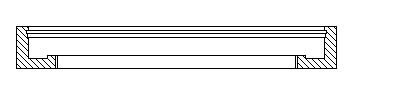

Diaphragm Mounting Ring and Diaphragm. The ring having an "Indent", on the front face, to identify it is of the 2072 Z 0009 type. Note the tapered edge to enable the "Snap-fit" into the frame |

|

|

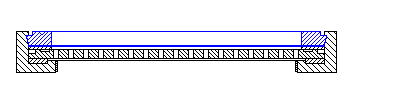

Diaphragm to Backplate, Insulated "Distance Ring" |

|

|

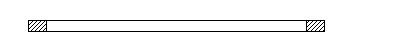

Backplate, "Electrode" |

|

|

Foam Ring |

|

|

Removable half of "Teflon" Capsule Frame. With a "Recess" that allows the diaphragm assembly to be a "Snap-fit" into the frame |

|

|

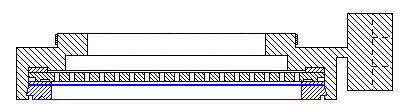

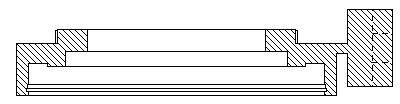

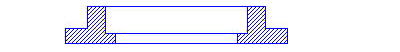

When the above parts are fitted together, we have the removable half of the capsule assembly. Note that the foam ring, between the backplate and frame, is now compressed. Thus all the parts are "Sandwiched" together |

|

|

Capsule Fame Spacing Ring, and provides additional electrical insulation, fits between the two halves of the capsule assemblies |

|

|

When the parts below are fitted together, we have the Fixed/Mounting half of the capsule assembly. Note that the foam ring, between the backplate and frame, is now compressed. Thus all the parts are "Sandwiched" together |

|

|

Fixed/Mounting half of "Teflon" Capsule Frame. With a "Recess" that allows the diaphragm assembly to be a "Snap- fit" into the frame |

|

|

Foam Ring |

|

|

Backplate, "Electrode" |

|

|

Diaphragm to Backplate, Insulated "Distance Ring" |

|

|

Diaphragm Mounting Ring and Diaphragm. The ring having an "Indent", on the front face, to identify it is of the 2072 Z 0009 type. Note the tapered edge to enable the "Snap-fit" into the frame |

|

|

For reasons of clarity, the above drawings did not show one of the most important item that helps to control the "Acoustic" properties of the capsule. That being the Teflon contact carrier and brass disc's, known as the "Carrier/Damping" assembly. This is used to help control/correct the frequency response and polar pattern of the capsule. |

|

|

The "Carrier/Damping" assembly consists of 4 parts/components. |

|

|

1 - Fixing screw |

|

|

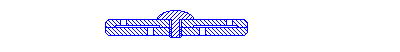

2 - "Upper Disc" A brass disc, with 24 holes towards and around the outer edge of the disc. This disc is recessed on the inner face |

|

|

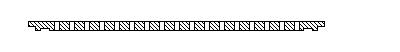

3 - "Lower Disc" A brass disc, with 12 holes towards and around the center fixing hole of the disc |

|

|

Disc's assembled, known as the "Acoustic Friction Element" Note the "Misaligned Holes" and "Air Cavity" |

|

|

4 - Contact "Carrier" Made from Teflon and used to carry the electrical pick-up contacts for the backplate electrodes and home to the "Acoustic Friction Element" |

|

|

The complete "Carrier/Damping" assembly |

|

|

Now we have all of the components required to build the 2072 Z 0009 capsule. The removable and fixed halves of the capsule are assembled, together with the associated frame "Spacing Ring" and the "Carrier/Damping" assembly, thus forming the finished unit. |

|

|

Fully assembled 2072 Z 0009 capsule |

|

|

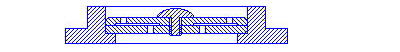

Cutaway/ Sectional view of the 2072 Z 0009 capsule |

|

| Let us now dismantle the 2072 Z 0009 capsule, and see what we find ! | |

|

The majority of this text, is the same as that for the 2072 Z 0005 capsule. The important difference, being the description of the Inner Disc assembly. |

|

|

Initially we have the complete capsule assembly, removed from the associated microphone. |

|

|

The capsule consists of two halves. For the sake of convenience, let us call them the "Removable" and "Fixed" halves. The fixed half having the mounting bracket, which unlike the "Brass" CK12, cannot be removed as a separate item. During manufacture, the two halves are screwed together and held in place by a Locktite type of adhesive. |

|

|

So let us start by separating the two halves of the capsule. Now we have the "Removable" and "Fixed" halves. |

|

|

The 2072 Z 0009 diaphragm and ring, being marked with an "Indent" on the front face of the mounting ring. Unlike the "Brass" CK12, where each diaphragm and mounting ring is held in place by 12 screws per diaphragm, the 2072 Z 0009 diaphragms and mounting rings are simply "Popped out" of the "Teflon" frame. The edge of the diaphragm mounting ring is tapered to allow this "Snap-fit" into the "Teflon" capsule frame. |

|

|

Electrical contact with the diaphragm being made via a small screw-in brass contact post. This accepts a slide-on connector or alternatively the screw-in post can be removed, enabling a suitable "Solder tag" to be fitted, before the post is refitted. |

|

|

Very thin insulated "Distance Rings" are used to determine the exact distance, air gap, between the rear surface of the diaphragm and front of the backplate. The distance ring rests on the machined reference, around the outer edge of the backplate. |

|

|

As with the original "Brass" CK12, these "Distance Rings" effecting the sensitivity of the capsule e.g. thinner the ring, the greater the sensitivity. The rings also having an influence on the frequency response and polar pattern of the final assembled capsule. |

|

|

The backplates now come into view. These are held in place simply by compression, due to the "Snap-fit" of the diaphragm and a rear mounted foam ring. Forming a sandwich of the parts. Therefore, at this stage of dismantling the capsule, the backplates will now just fall out of the frame ! |

|

|

Looking at the "Guillotined" marks around the perimeter of the backplates, they would appear to be "Pressed out", rather than machined to the required finish. |

|

|

The backplates would appear to be similar in design and appearance to that of the main backplates of the "Brass" CK12 design e.g. the position and number of holes. However, there is additional engineering, in the form of a recess and machined "Reference" surface, towards the outer edge of the backplate. |

|

|

Both the front and rear backplates sharing a common "Insulated" Teflon contact carrier. Due to the lack of space, then the gold plated brass contacts are somewhat narrower than those used in the 2072 Z 0005 capsule. The contact carrier lives in the very center of the capsule assembly and carries two spring contacts, one on either side of the carrier, thus making electrical contact with the rear of the associated backplate when the capsule is assembled. These contacts can just be seen through the diaphragm of the assembled capsule. Each one of these contacts being wired out of the "Fixed" half of the "Teflon" frame, to it's respective brass terminal, allowing for connection to the microphone wiring. The "Removable" half of the frame, just being a carrier for the diaphragm and associated parts. |

|

|

As the following is only intended as a guide to the "Assembly" of the respective parts, then the dimensions given, are only "Approximate". |

|

|

In the center, of the Teflon contact carrier, sits two brass inner disc's, being 13.5 mm in diameter by 1 mm thick. These are sandwiched together by a small screw. One disc has 12 holes, 0.5 mm diameter, on a radius of 2.8 mm and the other disc has 24 holes, 0.35 mm diameter, on a radius of 5.4 mm. The disc with 24 holes has a recess of 0.05 mm, this forming an "Acoustic" cavity between the two disc's when assembled. Similar in principal to the "Brass" CK12 design. |

|

|

The above carrier and disc's, known as the "Carrier/Damping" assembly, is physically situated within the air-gap that exists between the two halves of the assembled capsule. It acts as a "resistive acoustic path", and therefore has a great influence on the final sound quality and polar response of the finished product. |

|

|

So, The design of the "Carrier/Damping" assembly, used in the 2072 Z 0009 capsule, is one of the main reasons for the improvement in sound quality over that of the 2072 Z 0005 capsule. Indeed, this assembly helps to generate a "Presence Boost" from approx' 3kHz upwards, with a peak at around 4kHz and again, with a slightly higher peak, at 8kHz. This is something that the 2072 Z 0005 capsule lacked. Thus allowing the 2072 Z 0009 capsule to recreate a sound "Approaching" that of the original Brass CK12. |

|