----------

|

Curio's - Neumann's KK50 capsule assembly - 2nd type K50 capsule |

|

|

Small and simple |

|

|

The 2nd type capsule used an aluminum foil diaphragm, of approx' 12.5 mm diameter. The diaphragm being attached to the capsule body by twelve (12) small screws and a suitable clamping ring. |

|

|

Like the early design K50 capsule, the 2nd type uses a single backplate rather than a multi-layer type. Looking at the backplate, it appears to be made from a single piece of brass. This would require a lot of machining, and therefore generate a considerable waste of material and therefore increasing the production costs. |

|

|

The capsule body slides into the capsule case, and is held securely in place by three (3) grub screws. |

|

|

Electrical connections, in common with all K50 capsules, being a small pin protruding out of the front face of the capsule case and a pin protruding from the rear of the capsule. |

|

|

|

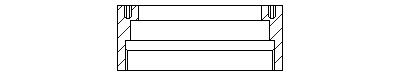

"2nd type" of the K50 capsule |

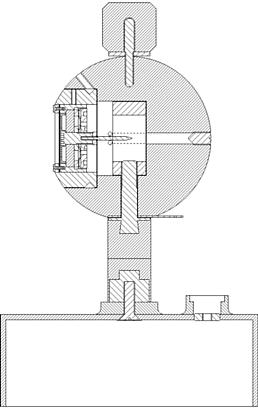

| Sectional views of "2nd type" K50 type capsule | |

| Note - For reasons of clarity, some fixing screws and hidden detail, is omitted. | |

|

Let us start by looking at "The Parts", that are utilized in the capsule assembly |

|

|

Capsule case. The capsule body fitting into the case and held in place by three (3) grub screws located around the outside of the case. The front face of the case, follows the same contour/radius as that of the Plexiglass sphere. Thus keeping the overall finished assembly, as spherical as possible |

|

|

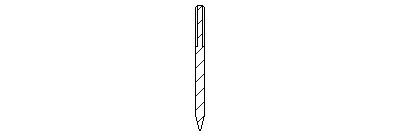

Very small screws used to secure the diaphragm ring, and diaphragm, to the capsule body. Twelve (12) screws are used, only two (2) are shown for clarity |

|

|

Diaphragm ring. This item holds the diaphragm on the body of the capsule. |

|

|

Aluminum foil diaphragm, approx' 12.5 mm diameter |

|

|

Capsule body, machined from brass |

|

|

Backplate, machined from brass. Containing ninety-one (91) holes. This precession engineered component, appears to be machined from a single piece of brass |

|

|

Backplate locating disc, made from perspex type material. Used to carry, and electrically insulate, the backplate assembly within the capsule body |

|

|

Brass spacing ring. Used like a thick washer to help hold the backplate assembly together |

|

|

Phosphor bronze crinkle washer. Used to help "Compress" the backplate assembly together |

|

|

Brass fixing ring. Used to lock the backplate assembly together. See complete backplate assembly |

|

|

Brass spacing ring. Used like a thick washer to help hold the backplate assembly within the capsule body |

|

|

Phosphor bronze crinkle washer. Used to help "Compress" the backplate assembly within the capsule body |

|

|

Brass fixing ring. Used to lock the backplate assembly within the capsule body. See complete capsule assembly, less the case |

|

|

Brass nut. Used to lock the backplate electrode pin into the backplate assembly |

|

|

Brass backplate electrode pick-up pin. Used to carry the electrical output of the capsule to the pick-up ring. See pick-up pin and nut together |

|

|

|

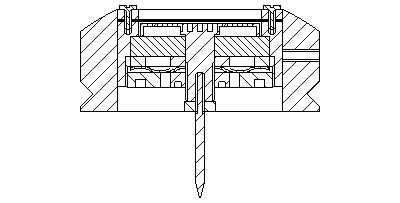

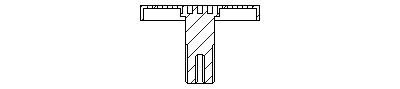

Sectional view of parts inside an 2nd type K50 capsule |

|

Sectional view of the above parts, assembled. to form the complete capsule. This is then fitted into the "Plexiglass" sphere assembly, to form the KK50, as we know it. |

|

|

|

Sectional view of 2nd type K50 capsule |

|

Finally, a "Cut-away / Sectional" view of the "2nd type" K50 capsule. Showing how all of the many components fit together. Being somewhat different to the design of the previous variants |

|

|

|

"Cut-away / Sectional" view of a "2nd type" K50 capsule |

|

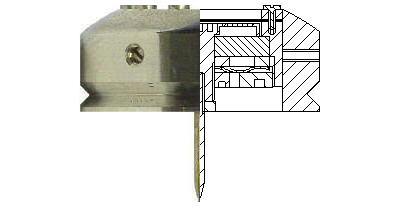

The KK50 assembly, complete with the 2nd type capsule. Further information about the whole KK50 assembly |

|

|

|

The KK50 assembly, complete with 2nd type capsule |