----------

|

Curio's - Neumann's KK50 capsule assembly |

|

|

As used in the legendary M50 microphone |

|

|

Designed as a follow up to the multi-pattern M49, the Omni-directional M50 was intended for single microphone pick-up i.e. Mono, for use in broadcasting and recording of orchestra's and small ensembles, etc. |

|

|

There can be no doubt that the M50 is one of Neumann's most sought after microphones. The M50 electronics being designed around the excellent Telefunken AC701 valve and the, large cored, Bv.11 matching transformer. This combination, together with the KK50 capsule assembly, allowed the M50 microphone to offer a performance that is very difficult to improve upon, even using modern technology. |

|

|

Various changes were made during the manufacture of the M50 microphone. Models being suffixed with an "a", "b" or "c" to show the stage of development e.g. M50b. See specification. |

|

|

The polar pattern, of the KK50 capsule assembly, being predominantly Omni-directional, becoming more directional at higher frequencies, together with a slight rise in output as the frequency increases. In a diffused sound field, the output is relatively flat, irrespective of frequency. |

|

|

As far as I am aware, there are three (3) variants of the actual capsule used in the KK50 assembly. If anybody knows of more, then please contact me. |

|

|

The K50 capsules used in the KK50 assembly, I will refer to them as being; Early type, 2nd type, Later type (Further information on the links) |

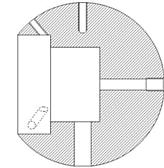

An example of an KK50 capsule assembly (Fitted with the 2nd type of K50 capsule) |

| What makes the KK50 so different ? | |

| Through the design of mounting the Omni-directional capsule within a spherical housing, whereby the diaphragm almost becomes a small percentage of the surface of the sphere, helps to obtain the characteristic sound the KK50 capsule gives us. Somewhat similar in principle to recent the B&K microphone and "slide on" ball combination. | |

| Let us not forget the old ST&C 4021 "Apple (Ball) and Biscuit" dynamic model, whereby the diaphragm also sits on the surface of a sphere. However, the "Biscuit" forms a screen to direct high frequencies, therefore enabling the microphone to offer an omni-directional pattern across the whole frequency spectrum. | |

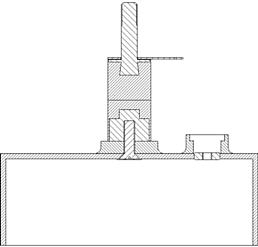

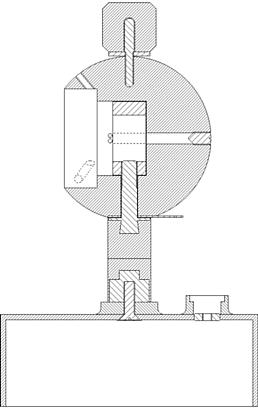

| Sectional views of KK50 capsule assembly | |

| Note - For reasons of clarity, some fixing screws and hidden detail, is omitted. | |

|

"The Parts", that are utilized in the capsule assembly (Less capsule) |

|

|

Neoprene bumper |

|

|

Mounting stud plastic cover |

|

|

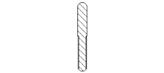

Threaded mounting stud |

|

|

Perspex washer |

|

|

The above items are fitted together, to form the upper locating bump |

|

|

Capsule assembly, upper locating bump. This screws into the top of the Plexiglass sphere, and used to hold the capsule assembly in the correct position, through the use of a small metal socket in the top of the microphone grill cage |

|

|

The most distinguishing feature of the KK50 capsule, is the Plexiglass (a kind of perspex type material) sphere |

|

|

The Plexiglass sphere. A precision engineered component that carries the actual capsule element. With the various required fixing holes etc. The rear edge of the capsule being a precision fit against the seat within the large mounting hole. The capsule is then held securely in place by three evenly spaced grub screws. |

|

|

The electrical connection to the rear backplate of the capsule, is made via a pick-up ring/spring wire assembly. Whereby, the capsule rear pin, passes through two closely spaced spring wires to make electrical contact |

|

|

Backplate electrode pick-up ring assembly. Consisting of a metal ring with two parallel spring wires fitted across it's diameter. A mounting thread is cut into the lower edge of the item, to facilitate fixing within the sphere |

|

|

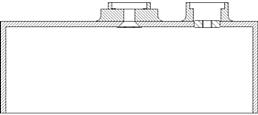

The KK50 capsule is mounted on a pillar, which is in turn mounted to the base plate. The later fitting on top of the microphone electronics |

|

|

The base plate and capsule mounting pillar |

|

|

The capsule mounting pillar is assembled from the following items |

|

|

Solder tag. Used for electrical pick-up of the capsule backplate electrode |

|

|

Threaded metal mounting stud. This passes through the solder tag and a hole in the Plexiglass sphere, then screws into the backplate electrode pick-up ring assembly. Thus securely holding the Plexiglass sphere to the mounting pillar, and providing electrical contact between the solder tag and the capsule backplate |

|

|

Mounting pillar, rubber type of material, constructed from two separate sections that are vulcanised together. The use of a rubber type of material helping to isolate the capsule from structural vibrations, also providing excellent electrical insulation |

|

|

Threaded metal mounting socket. A screw passes through the base plate into the mounting socket. Thus securely holding the mounting pillar to the base of the assembly |

|

|

The capsule assembly base plate, is constructed out of a perspex type of material. The collars used, to protect the three (3) assembly mounting screws, are glued onto the base plate. As is the larger, pillar mounting step in the center of the base plate. Two (2) of the assembly mounting screws being used for electrical contact between the capsule and the microphone electronics |

|

|

Fixing screw, that secures the base plate to the mounting pillar. When assembled, the head of the screw is coated with a screw locking solution. |

|

|

The above items all fit together to form the KK50 assembly |

|

|

The complete KK50 assembly, less the K50 capsule element. There is the addition of a grub screw to the rear of the backplate electrode pick-up ring. This is removed, to access the capsule backplate electrode pin, during capsule removal. For reasons of clarity, the three (3) capsule fixing grub screws and three (3) electrical terminating/assembly mounting screws are not shown |

|

| Various K50 type capsules used in the KK50 assembly | |

|

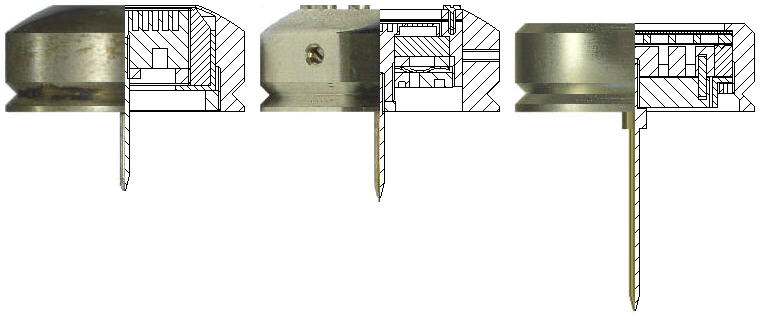

Cutaway views of the different versions of K50 capsules used in the KK50 capsule assembly. Left to right being; Early type, 2nd type, Later type (Further information on the links) |

|

|

|